Safety equipment has come a long way from its rudimentary beginnings. Over the course of a century, it has evolved into sophisticated gear designed to protect workers across various industries.

This evolution has been driven by technological advancements, increased awareness of workplace hazards, and the relentless advocacy of professionals like a New York construction accident attorney who advocates for workplace safety.

Understanding how safety equipment has developed over time offers valuable insights into the importance of continuous innovation and legal advice. Below, discover the history and advancements of safety equipment, highlighting key milestones and the role of legal professionals in promoting worker safety.

What Did Early Safety Equipment Look Like?

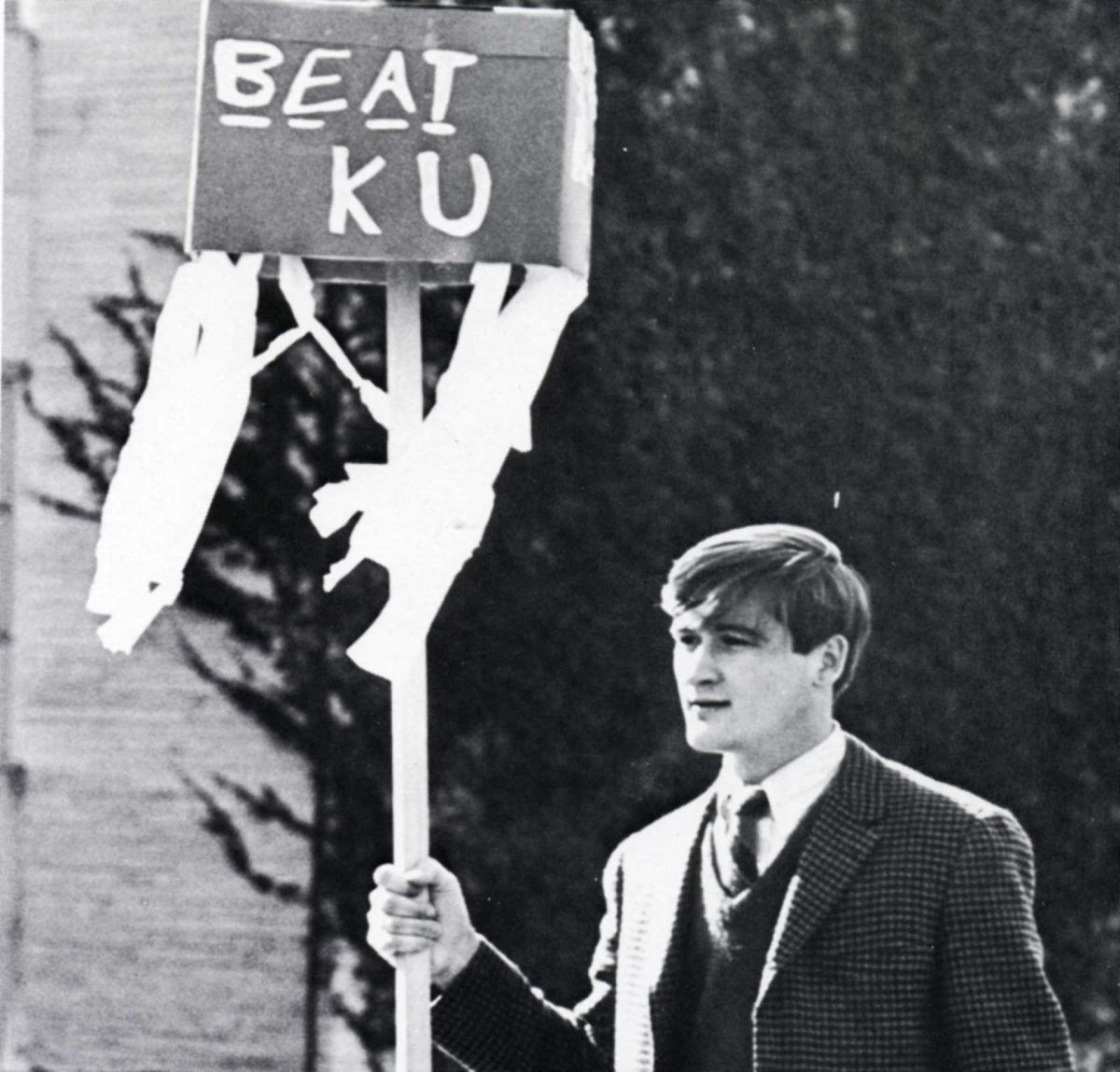

In the early 20th century, safety equipment was rudimentary and often ineffective. Workers in high-risk industries like construction, mining, and manufacturing relied on minimal protective gear that provided limited protection.

For instance, basic cloth caps and leather gloves were among the earliest forms of head and hand protection and provided little defense against serious injuries.

Accidents were common, and the lack of adequate safety measures often led to severe injuries or fatalities. During this time, the role of the attorney became crucial in advocating for worker safety. Legal professionals fought tirelessly for better working conditions and the implementation of safety standards. Their efforts helped pave the way for future safety advancements.

Early safety gear gradually improved as industrial accidents drew public attention and prompted legislative changes. The introduction of early hard hats and protective eyewear marked the beginning of a slow but steady evolution in equipment. These initial steps laid the groundwork for more comprehensive safety measures.

What Advances to Safety Equipment Have Been Made?

The mid-20th century saw significant advancements in safety equipment, largely driven by post-World War II industrial growth and increasing awareness of workplace hazards. This period marked the introduction of more sophisticated and effective safety gear, including hard hats, steel-toed boots, and safety goggles.

Hard hats, made from durable materials like aluminum and fiberglass, became standard in the construction industry and provided much-needed head protection. Steel-toed boots became vital for workers in manufacturing and construction environments, while safety goggles were developed to shield workers’ eyes from debris and hazardous substances.

Stricter safety regulations and standards accompanied these technological advancements. Government agencies like the Occupational Safety and Health Administration (OSHA) in the United States were established to enforce workplace safety laws.

Attorneys played a pivotal role during this period by advocating for safer workplaces and representing injured employees. Their efforts ensured employers were held accountable for providing safe working conditions and compliant equipment.

What Are Modern Innovations in Safety Equipment?

In recent years, safety equipment has undergone remarkable changes and started incorporating cutting-edge technology and innovative materials. Modern safety gear is designed to be more effective, comfortable, and adaptive to various work environments.

Smart technology has revolutionized safety equipment, with wearable devices now capable of monitoring workers’ health and safety in real time. These devices can track vital signs, detect hazardous conditions, and alert workers to potential dangers, significantly reducing the risk of accidents.

Materials science has also contributed to developing lightweight, durable, and more protective gear. Innovations like advanced polymers and impact-resistant composites have improved the performance of helmets, gloves, and protective clothing. Ergonomic designs ensure safety equipment fits better and is more comfortable to wear, encouraging consistent use.

Government regulations and legal standards also continue to drive innovation in safety equipment. Regulatory bodies like OSHA and the European Agency for Safety and Health at Work set stringent safety requirements that manufacturers must meet.

What Safety Equipment Is Used in Specific Industries?

Different industries have specific safety requirements, leading to safety equipment tailored to particular hazards, some of which are listed below.

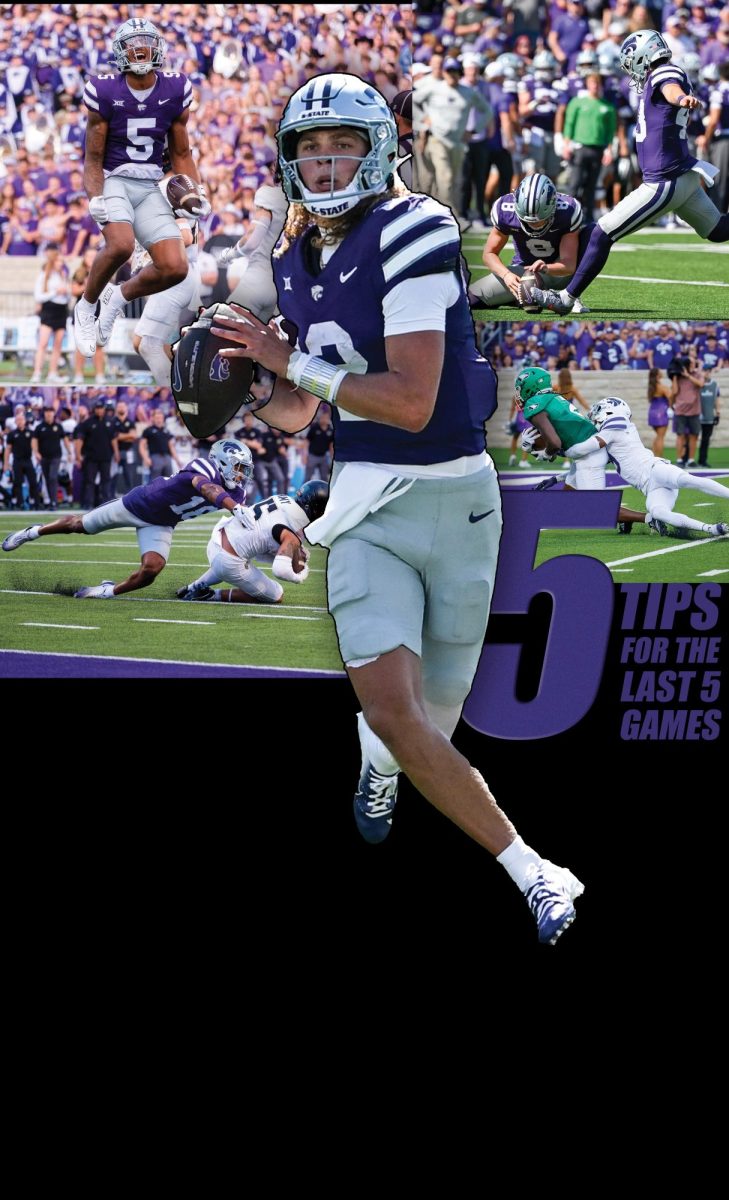

Construction

Workers rely on hard hats, harnesses, and high-visibility clothing to protect against falls, head injuries, and vehicle accidents.

Healthcare

Personal protective equipment (PPE) like gloves, masks, and face shields are critical, highlighted by the COVID-19 pandemic.

Manufacturing

Automated safety systems, protective gloves, and safety goggles protect workers from machinery-related injuries and chemical exposure.

The History of Safety Gear: A Constant Evolution

The evolution of safety equipment reveals a relentless pursuit of worker protection driven by technological advancements and legal advocacy. From the rudimentary gear of the early 20th century to today’s smart, ergonomic designs, each advancement reflects a commitment to safety.

As industries evolve and new hazards emerge, continuous innovation in safety equipment remains crucial. Ensuring worker safety requires ongoing collaboration between technology developers, regulatory bodies, and attorneys dedicated to upholding safety standards.