Main Takeaway: While wooden pallets offer a lower upfront cost, plastic pallets deliver significantly greater durability and a longer usable life. When evaluated on a total cost of ownership basis-including purchase price, maintenance, repair, replacement frequency, and lifecycle span-plastic pallets often prove cost-competitive with wooden pallets despite higher initial investment.

Used Pallets: For businesses that care about minimizing initial costs, used wooden pallets are the most economical initial purchase option, typically costing 30-50% less than new wooden pallets. However, used pallets add to the cost of ownership inherent in wooden pallets. They often require immediate repair, have a shorter remaining useful life, and may have quality inconsistencies that affect performance.

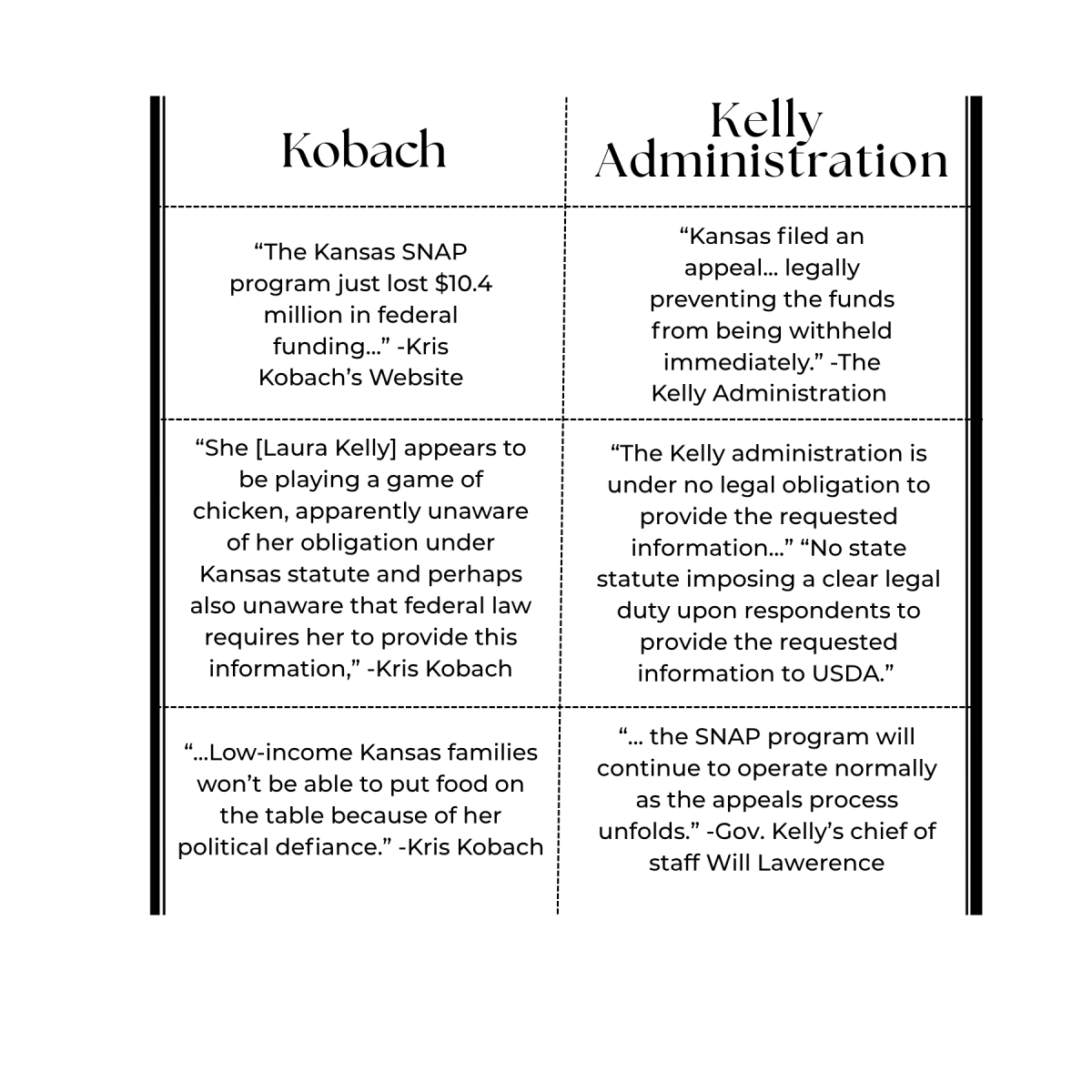

Upfront Purchase Costs

Wooden pallets remain the most economical option in terms of initial outlay. In the United States, a new standard 48″ x 40″ wooden pallet typically costs between $11.25 and $30. Used or recycled wooden pallets can be acquired for as little as $4.25 to $15.

In contrast, new plastic pallets command higher market prices, generally ranging from $10 up to $120 per unit, depending on design complexity, material grade (e.g., polypropylene vs. high-density polyethylene), and specialized features such as rackability or nestability. Used plastic pallets, benefiting from refurbishment, are available for roughly $5 to $50.

| Pallet Type | New Pallet Cost (48″x40″) | Used Pallet Cost |

|---|---|---|

| Wooden | $11.25 – $30.00 | $4.25 – $15.00 |

| Plastic | $10.00 – $120.00 | $5.00 – $50.00 |

Lifecycle and Total Cost of Ownership

Expected Service Life

Wooden pallets normally endure between 3 and 5 years under typical circulation, equating to roughly 15-20 supply-chain trips before extensive repair or retirement is needed. Factors such as moisture, overloading, and exposure to rough handling accelerate degradation.

Plastic pallets, constructed from injection-molded polypropylene or HDPE, exhibit lifespans of 8 to 15 years-often doubling or tripling that of wood-and can withstand upwards of 100 trip cycles before failure. Their resistance to rot, mold, chemicals, and pests underpins this longevity.

Maintenance and Repair

Wooden pallets require periodic inspection and straightforward repair-replacing broken boards or nails-to extend usable life. Maintenance costs for repairs typically amount to 20% of new-purchase price per repair cycle. Heat treatment for ISPM 15 compliance adds further cost for export pallets.

Plastic pallets demand minimal maintenance due to non-porous surfaces impervious to moisture and contaminants. However, once a plastic pallet is irreparably damaged (e.g., cracked runners), it generally must be recycled rather than field-repaired.

Cost Comparison Over Useful Life

Calculating lifecycle cost per year provides a more complete comparison:

Wooden Pallet:

- Average purchase $20, lifespan 4 years → $5 per year (excluding repair)

- Add average repair/maintenance $5 per year → $10 per year

Plastic Pallet:

- Average purchase $60, lifespan 10 years → $6 per year (no repair assumed)

Thus, lifecycle expenses converge: wooden pallets at $10 per year vs. plastic pallets at $6 per year, with plastic pallets delivering better reliability and fewer service interruptions.

Durability and Performance Factors

Structural Integrity

Wood is susceptible to splintering, cracking, and fungal growth when exposed to moisture, compromising safety and load integrity. Overloaded or improperly handled wooden pallets can fail unexpectedly under dynamic loads.

Plastic pallets maintain structural rigidity under heavy loads-static capacities often exceed 4,000 lb and dynamic capacities up to 2,200 lb-while remaining resistant to impact damage. Their one-piece construction eliminates loose boards and protruding nails, reducing workplace injuries.

Environmental and Hygiene Considerations

Wooden pallets harbor moisture, bacteria, and pests due to porous surfaces, making them unsuitable for sterile applications without extensive cleaning and fumigation. Heat treatment mitigates pest risk but does not address inherent porosity.

Plastic pallets feature closed, smooth surfaces that resist contamination and facilitate automated washing and sanitization, meeting strict hygiene standards in food, beverage, and pharmaceutical industries.

Environmental and Regulatory Impacts

Wooden pallets are derived from renewable resources and are biodegradable; at end of life, they can be chipped for mulch or biofuel. However, fluctuations in lumber supply and pricing-exacerbated by global events-introduce volatility in procurement costs.

Plastic pallets are recyclable, often manufactured from post-consumer or industrial recycled resin, supporting circular manufacturing models. Although based on non-renewable feedstocks, extended service life and recyclability reduce net environmental footprint when managed properly.

Application-Driven Selection

When to Choose Wooden Pallets

- Tight capital budgets favor lower upfront costs

- Short-distance or single-use shipments where loss or damage risk is high

- Applications tolerating periodic repairs and replacements

When to Choose Plastic Pallets

- Long-term pooled or closed-loop supply chains, maximizing reuse cycles

- Hygienic environments requiring frequent cleaning or sterilization

- Automated handling and racking systems that demand consistent dimensions

- Export shipments exempt from ISPM 15 fumigation regulations

While wooden pallets remain cost-effective for low-capital or single-use scenarios, plastic pallets offer superior durability, hygiene, and long-term cost efficiency in high-throughput or regulated environments. Evaluating total cost of ownership-rather than purchase price alone-reveals that plastic pallets often provide the best return on investment over their extended service life.