When investing in a Fibre laser cutting machine, getting the right fit for your business isn’t just about power and precision—it’s about making a smart, long-term decision. With so many options available, it’s easy to become overwhelmed by technical jargon or distracted by flashy features that may not meet your actual needs. That’s why it’s crucial to understand what truly matters before making a purchase. From laser source quality to software compatibility and after-sales support, knowing what to check ahead of time can save you both money and headaches in the long run. In this guide, we’ll break down the key factors to consider so you can confidently choose the right fibre laser cutting machine for your operations.

Here’s What To Check Before Buying A Fibre Laser Cutting Machine

Laser power and cutting capacity

One of the most important factors to consider before purchasing a fibre laser cutting machine is its laser power and cutting capacity. These two factors directly influence the materials the machine can handle and its operational efficiency. A higher wattage laser typically allows for faster cuts and the ability to slice through thicker materials, making it ideal for heavy-duty industrial use.

On the other hand, smaller operations may benefit more from a moderate-power laser that strikes a balance between performance and cost. Assessing your specific workload and material types will help you choose a machine with the right power and capacity to meet your production goals.

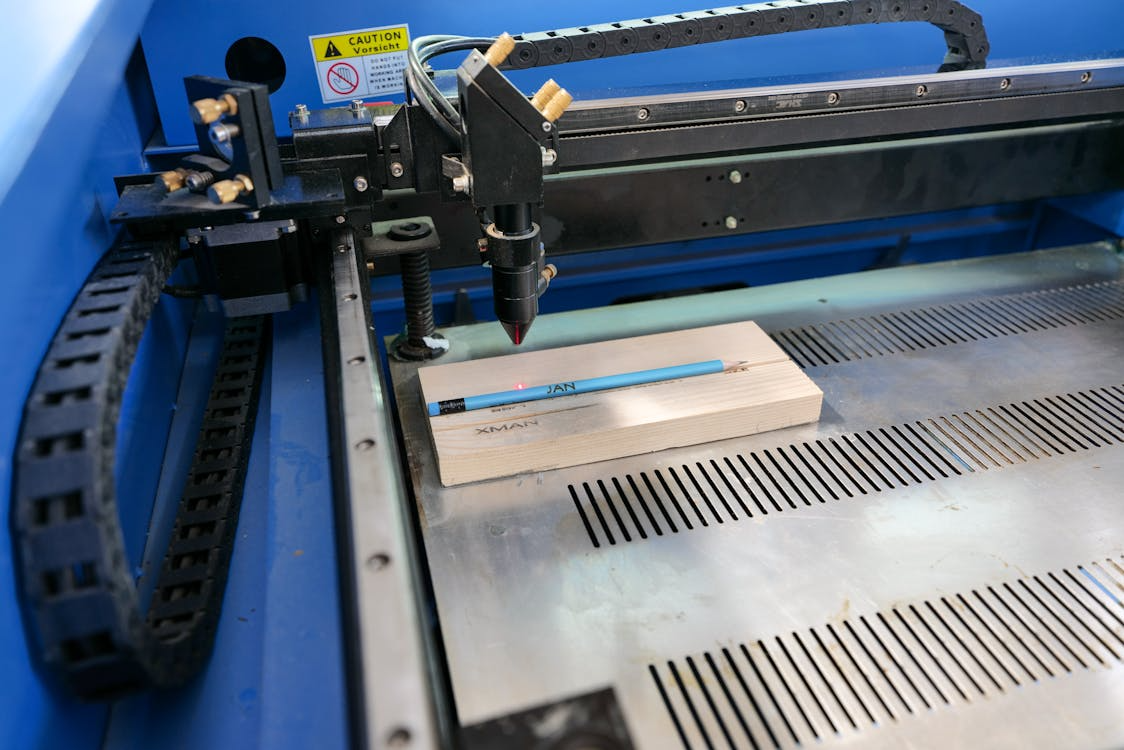

Machine build quality and durability

Another critical factor to consider before purchasing a fibre laser cutting machine is its overall build quality and durability. A well-constructed frame and robust components ensure long-term stability, consistent performance, and resistance to wear and tear over time.

Machines built with precision-engineered parts and heavy-duty materials are better equipped to handle continuous operations without frequent breakdowns. Evaluating the quality of materials used, welding techniques, and structural reinforcements can provide insight into how well the machine will perform in demanding environments.

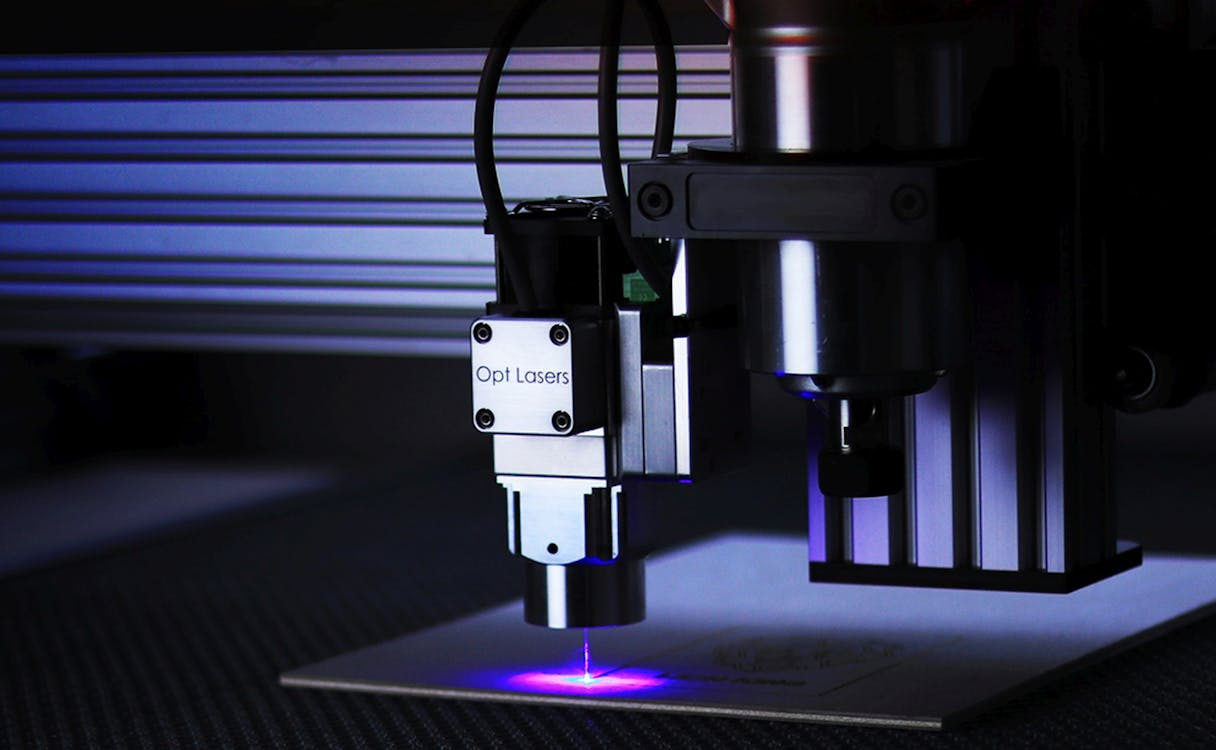

Type and brand of laser source

A key factor to consider before purchasing a fibre laser cutting machine is the type and brand of the laser source it utilizes. The laser source is the heart of the machine, and its quality has a major impact on cutting performance, reliability, and operational lifespan.

Established brands like IPG, Raycus, and nLIGHT are recognized for their consistent output, stable performance, and superior support. Choosing a reputable laser source can reduce downtime and ensure compatibility with future upgrades or replacements. Verifying the brand’s track record and warranty terms can help you avoid unexpected issues and make a more informed investment decision.

Cutting speed and precision

Cutting speed and precision are essential aspects to check before buying a fibre laser cutting machine, especially if your business relies on fast turnaround and high-quality results. A machine that offers high cutting speeds without compromising on accuracy can significantly boost productivity and reduce waste.

Look for features such as advanced motion control systems, stable beam quality, and precision-guided components that ensure clean, consistent cuts. Evaluating real-world performance metrics—not just specs on paper—can help you determine whether the machine meets your requirements for both speed and fine detail.

Software compatibility and ease of use

Software compatibility and ease of use are crucial factors to consider before buying a fibre laser cutting machine. The software controls everything from design import to cutting parameters, so it needs to be intuitive, responsive, and compatible with commonly used file formats.

A user-friendly interface reduces the learning curve for operators and minimizes the risk of errors during production. Additionally, having software that integrates well with your existing systems and supports updates or customization can make daily operations smoother.

Automation features and upgrade options

When evaluating a fiber laser cutting machine, it’s essential to examine the automation features and upgrade options it offers. Automation capabilities, such as auto-focus, material loading systems, and real-time monitoring, can drastically improve efficiency and reduce manual labor.

These features are especially valuable in high-volume production environments where speed and consistency are crucial. Additionally, selecting a machine with flexible upgrade paths—such as the ability to add higher-wattage lasers, improved cooling systems, or advanced software—can extend the machine’s usability as your business expands.

Energy efficiency and maintenance needs

Energy efficiency and maintenance needs are crucial factors to consider before purchasing a fibre laser cutting machine, especially if you’re planning for long-term operational costs. Machines that are designed to consume less power without sacrificing performance can significantly reduce your energy bills over time.

At the same time, consider how often the machine needs servicing and how easy it is to perform routine maintenance. Models with accessible components, modular designs, and self-diagnostic features can minimize downtime and service expenses.

Safety features and certifications

Safety features and certifications are essential to check before purchasing a fibre laser cutting machine, as they directly impact the operator’s well-being and compliance with regulations. A reliable machine should include built-in safety features, such as protective enclosures, emergency stop buttons, and real-time fault detection and alerts.

Additionally, certifications from recognized industry standards—such as CE, ISO, or FDA—indicate that the machine has passed strict safety and quality tests. These not only help reduce the risk of workplace accidents but also simplify approval processes for industrial use.

After-sales service and warranty terms

After-sales service and warranty terms are crucial to consider before purchasing a fibre laser cutting machine, as they directly impact long-term support and peace of mind. A machine is only as reliable as the assistance you receive when something goes wrong.

Look for manufacturers or suppliers that offer responsive technical support, clear maintenance guidance, and easy access to spare parts. A solid warranty that covers both the laser source and major components can protect your investment from unexpected issues.

Final Words

Choosing the right fibre laser cutting machine goes beyond just comparing price tags—it’s about aligning the machine’s capabilities with your specific operational needs. From laser power and cutting precision to software compatibility, safety features, and after-sales support, each factor plays a key role in ensuring long-term value and efficiency. Taking the time to thoroughly evaluate these aspects will help you avoid costly missteps and invest in a machine that truly supports your productivity goals.